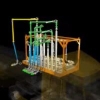

Bottom Loading Fuel Arms

Bottom Loading Fuel Arms by Carbis Loadtec allow operators to have all the convenience they need from a low cost and efficient hose loading arm.

Petroleum tanker filling via low level connections provides operators with the potential to load multiple compartments simultaneously as well as having automatic high level alarm for each compartment.

Carbis Loadtec is able to supply high quality and durable Bottom Loading Fuel Arms with long warranties that will give up to six liquid arms and one vapour arm per bay. Combined with our API coupler range we provide loading arms as stand-alone products, or along with our meter skid systems we provide packaged solutions for tanker filling working to all recognised design and functional standards.

The Bottom Loading Fuel Arms are fitted with spring cylinders which allow easy vertical position adjustment and incorporate our specially made composite hose for long life and chemical resistance.

The arms can optionally be fitted with breakaway couplings when required.

The standard configuration bottom un/loading arm with four swivels has been a dependable, safe and clean method for tanker fill for many years.

Did you know?

The lighter, the better

The combined weight of a 4-metre DN80 chemical hose, dry break coupler and a full load of liquid is approximately 50kg. The weight of a fully laden bottom loading arm is 0kg. Which would you prefer to handle?

Learn more about our range of safe access and bulk liquid loading systems

Call us on +44 1303 81 3030

Or fill in our Contact Us page

Did you know?

We also offer:

- servicing

- installation

- maintenance

Find out how we can help with your project.